This can vary based on the site conditions. Up to 24 cash back Consucon Dewatering Ino ducon.

Deep Well Dewatering System In Construction

In cases when wellpoints and deep wells are not suitable methods for dewatering the use of eductors can be considered.

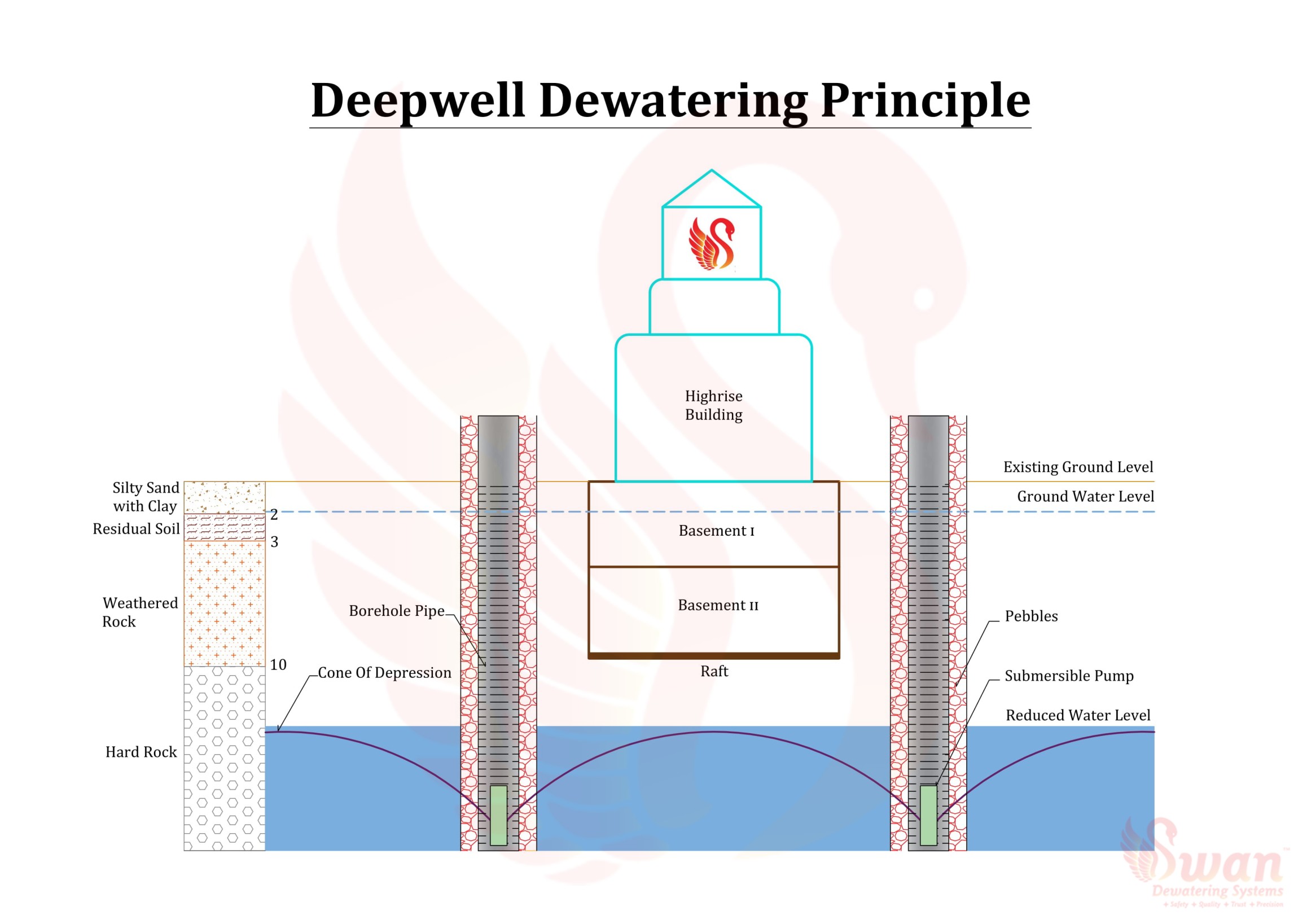

. Deep well dewatering system uses a series of drilled wells to lower the groundwater level. In this methods of dewatering the ground water flow is diverted into deep well-points in the ground and the part to be excavated is kept free from ground water. Whether its a planned project or an emergency were here to assist you.

Single Chapter PDF Download 4200. Wellpoint dewatering system has proved a versatile and effective technique for dewatering low flows from silty sands and high flows from coarser sands and gravels. Unlimited viewing of the articlechapter PDF and any associated supplements and figures.

The design development included a review of monitoring feedback obtained during the pumping-well installation a pumping test and the dewatering system start-up. For deep well dewatering system the pumps are available from sizes of 3 ro14 inches that have capacities ranging from 500 to 5000 gallons per minute. Deepwell Dewatering Systems Lower Groundwater Levels Wj Uk More effective than deep well dewatering system.

Tor Kelley Dewatering to prepare design submittals for a deep well dewatering system to achieve required drawdowns for an approximate 25000 SF plant expansion with the deep-est portions extending 25 feet below grade. Ad Call Our Team of Experts Find How We Can Help With Your Well Point Dewatering. Deep Well Dewatering Systems tend to be used where the excavation depth exceeds the maximum limits for a wellpoint system and a large quantity of water needs to be extracted.

A wellpoint dewatering system consists of a series of shallow wells known as wellpoints. This method is ideal for deep excavations with moderate to high soil permeability soils like granular soil and. Lower the ground water tab le to 20 m below the botto m of e xcavation.

The method of excavation and reuse of the excavated soil may also have a bearing on the need for dewatering. Malcolm has years of experience in dewatering projects throughout the United States and our complete design and installation services can help in even the most challenging underground conditions. Design of a dewatering system requires the determination of the number size spacing and penetration of wells or wellpoints and the rate at which water must be removed from the pervious strata to achieve the required groundwater lowering or pressure relief.

A deep well system would be also be used if space is limited as. Articlechapter can be downloaded. In short NCS Fluid Handling Systems provides a complete line of dewatering services and well-point dewatering systems to satisfy all your well point dewatering ground water control ground stabilization deep well dewatering sewage bypass river diversion water pumping and deep well pump applications.

Deep well systems are often used for dewatering slopes and excavations when large drawdowns are required. Deep Well System Design The screen filter pack and pump size are designed to match the formation allowing each well to pump at its maximum Deep wells are typically drilled to depths of 30-100ft Equipped with pumps that can produce as little as 5gpm or as much as 1000 gpm Highly effective tool for. Articlechapter can be printed.

The system is flexible that can be used for any well depth spacing and different pump capacities. Deep wells are such and submersible pumps installed within them. The important parts of a well point system are as follows.

The capacity of the pumps as well as the number depth and spacing of deep wells may vary depending on the site conditions. Articlechapter can not be redistributed. Deep well dewatering system can drain out water up to 24m depth.

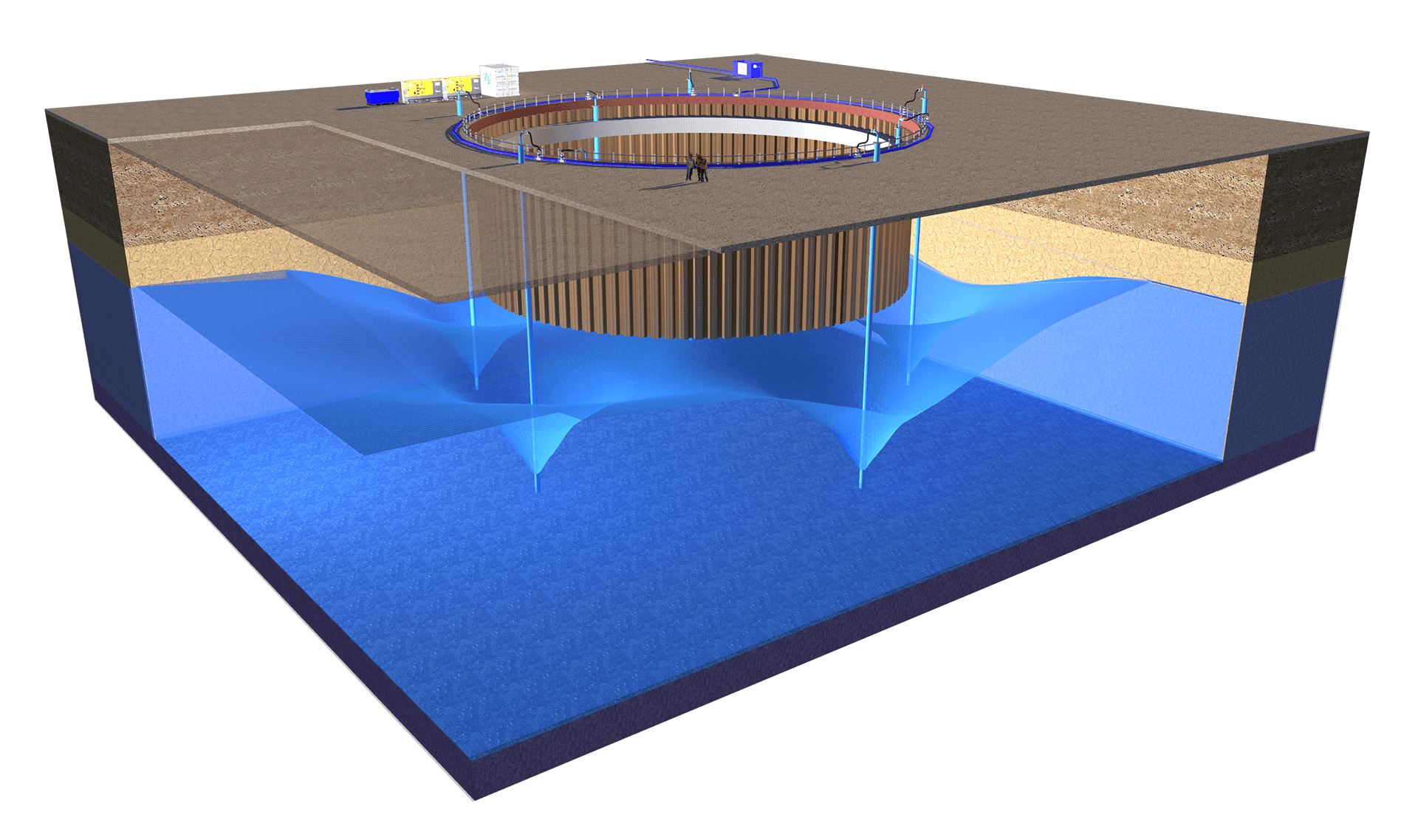

The method is applied to a dewatering case history and proves to. The dewatering system consists of twelve pumping wells located 5 feet from the crown of the excavation slope. Deep Well System Design The screen filter pack and pump size are designed to match the formation allowing each well to pump at its maximum Deep wells are typically drilled to depths of 30-100ft Equipped with pumps that can produce as little as 5gpm or as much as 1000 gpm Highly effective tool for.

The wells are provided with 40 feet of 10-inch diameter screens and the pumping rate at each well is assumed equal to 1150 gpm. This type of system generally consists of an array of pumping wells located near the excavation or slope. Well points are prepared at a distance of about 1m around the area to be excavated.

The method analyses three dimensional flow to the multiwell systems by considering the two end points to the initial fast phase of water table fall. They are ideal for keeping water away from construction trench areas enabling work to be carried out in dry and stable conditions. Ture in event of failure of the dewatering system.

Wellsare large-diameter greater than 6 inches holes drilled relatively deep greater than 10 feet and contain slotted casings and downhole pumps. Assume the quantity of well disc harge 60 m³. Design the dewatering system f or the excavation shown in figure below to.

This will help to suit the geometry of excavation. Ad Global Leader In Industrial Supply And Repair Services. Free Shipping Over 199.

Browse Our Site Today. Features of Deep Well Dewatering System. Dewatering Using the Eductor System.

A cased borehole can be sunk using well drilling or bored piling rigs to a depth lower than the required dewatered level. A cased borehole can be sunk using well drilling or bored piling rigs to a depth lower than the required dewatered level. A Wellpoint Dewatering system is a versatile cost-effective pre-drainage solution that features individual wellpoints which are closely spaced around the excavation.

The active pumping system must be set below the. These factors as well as the construction schedule must be determined and evaluated before proceeding with the design of a dewatering system. The combined effect of the array lowers the groundwater table over a wide area.

KUE performed calculations and determined the required spacing and screen depths to dewater the excavation to depths of 30 feet. This technique utilizes vacuum to assist in lowering groundwater levels to create a stable dry working environment. We install these wellpoints at a pre-determined depth and appropriate spacing around an excavation.

The design of dewatering pumps chosen the standby power equipment and the power supply is influenced significantly by the reliability of ground water control for a particular project. Wells work best in soils consisting of sand or sand and gravel mixtures and can dewater large areas to great depths. The diameter will be 150 200 mm larger then the well inner casing which in turn is sized to accept the submersible pump.

Deep well dewatering system uses a series of drilled wells to lower the groundwater level. System Design The objectives of a dewatering system will depend on many factors and no two dewatering systems are the same. A new design method for deep well dewatering systems is given.

Ad Do Your Best Work with Tsurumi Products.

Deep Well Dewatering System In Construction

Deep Well Dewatering Asp Piling Dewatering Systems

Deep Well Dewatering System Pds 25 Years Expertise

Deep Well Dewatering Contractor Services In Chennai 91 90254 06791 Bangalore 91 90254 06793 Ernakulam 91 90254 06792 Cochin

Deepwell Dewatering Systems Lower Groundwater Levels Wj Uk

0 comments

Post a Comment